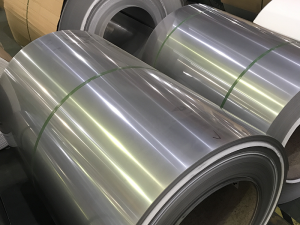

410S Stainless Simbi Coil

Tsanangudzo

Zvinodiwa:

1.Standard: ASTM A240, JIS G4304, EN10088

2. Giredhi: 200series&300series&400series

3. Ukobvu: 0.03mm - 6.0mm

4. Upamhi: 8mm-600mm

5. Kureba: sekukumbira kwevatengi

6. Surface: 2D, 2B, BA, Mirror yapera, N04, Hair Line, Matt kupera, 6K, 8K

7.Technology: kutonhora kunotorwa / kutonhora kwakaputika / kupisa kunopisa

Zvekushandisa:

| Type | Giredhi | Giredhi | Chemical Component % | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Zvimwe | |||

| Austenitic | 201 | SUS201 | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 | - |

| 202 | SUS202 | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0.060 | ≤0.030 | ≤1.00 | - | ≤0.25 | - | ||

| 301 | 1.4310 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | ≤0.10 | - | |

| 304 | 1.4301 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304L | 1.4307 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304H | 1.4948 | 0.04-0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309 | 1.4828 | ≤0.20 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309S | * | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 310 | 1.4842 | ≤0.25 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 310S | * | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 314 | 1.4841 | ≤0.25 | 23.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | 1.50-3.00 | - | - | - | |

| 316 | 1.4401 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316L | 1.4404 | ≤0.030 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316Ti | 1.4571 | ≤0.08 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | 0.1 | Ti5(C+N)~0.70 | |

| 317 | * | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 317L | 1.4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 321 | 1.4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 321H | * | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 347 | 1.4550 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C% -1.10 | |

| 347H | 1.494 | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C% -1.10 | |

| Duplex | 2205 | S32205 | ≤0.03 | 22.0-23.0 | 4.5-6.5 | ≤2.00 | ≤0.030 | ≤0.020 | 3.0-3.5 | ≤1.00 | - | 0.14-0.20 | |

| 2507 | S32750 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.20 | ≤0.035 | ≤0.020 | 3.0-5.0 | ≤0.80 | 0.5 | 0.24-0.32 | ||

| Ferrite | 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0.040 | ≤0.020 | - | ≤1.00 | - | ≤0.030 | Ti6(C+N)~0.50 Nb:0.17 |

| 430 | 1Kr17 | ≤0.12 | 16.00-18.00 | - | ≤1.0 | ≤0.040 | ≤0.030 | - | ≤1.0 | - | - | - | |

| 444 | S44400 | ≤0.025 | 17.50-19.50 | 1 | ≤1.00 | ≤0.040 | ≤0.030 | 1.75-2.5 | ≤1.00 | - | 0.035 | Ti+Nb:0.2+4(C+N)~0.80 | |

| Martensite | 410 | 1Kr13 | 0.08-0.15 | 11.50-13.50 | 0.75 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 410S | * | ≤0.080 | 11.50-13.50 | 0.6 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420 | 2Cr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| PH | 630 | 17-4PH | ≤0.07 | 15.00-17.50 | 3.00-5.00 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 17-7PH | ≤0.09 | 16.00-18.00 | 6.50-7.50 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | ≤0.50 | - | Al 0.75-1.50 | |

| 632 | 15-5PH | ≤0.09 | 14.00-16.00 | 3.50-5.50 | ≤1.00 | ≤0.040 | ≤0.030 | 2.00-3.00 | ≤1.00 | 2.5-4.5 | - | Al 0.75-1.50 | |

Basic information

410s Stainless Steel Coil, ine yakanaka corrosion resistance uye machinability, ibasa rakazara simbi uye yekucheka chishandiso simbi.410S imhando yesimbi inogona kuvandudza kusimba kwekuora uye kuumbwa kwesimbi 410.410S isimbi yakasimba yakasimba iyo inogona kuwedzera kuvandudza kusimba kwe410 simbi.Inoshandiswa kune turbine blades uye yakakwirira tembiricha zvikamu.

• Zvinyorwa: AISI 410s, ASTM 410s

• Inopedza: Ba surface, 2b surface, No.1 (white skin), 2D surface, No.4 (frosted), HL (wire drawing), 8K surface ine unhu hwakanaka

•Mill tolerances pamusoro ukobvu & flatness applies.Call JM Steel kana uchida chaiwo saizi kana zviyo nhungamiro.

410S Hunhu machining tekinoroji

1D - Iyo yepamusoro ine discontinuous granular chimiro, inozivikanwawo sefog surface.

Kugadziridza tekinoroji: inopisa kukungurutswa + annealing pfuti peening pickling + inotonhora rolling + annealing pickling.

2D - Ruvara ruchena zvishoma.

Kugadziridza tekinoroji: inopisa kukungurutswa + annealing pfuti peening pickling + inotonhora rolling + annealing pickling.

2B -- Sirivha chena ine kupenya kuri nani uye flatness pane 2D pamusoro.

Kugadzira tekinoroji: inopisa kukungurutswa + kupfutidza pfuti peening pickling + inotonhora kukunguruka + annealing pickling + kudzima uye kudzikama.

Ba - Yakanakisa yepasi gloss, yakakwirira kuratidza, senge girazi pamusoro.

Kugadziridza tekinoroji: inopisa kukungurutswa + kupfutidza pfuti peening pickling + inotonhora kukunguruka + annealing pickling + pamusoro pekupukuta + kudzima uye kupisa kutenderedza.

No.3 -- Kubwinya kwakanaka, nzvimbo yezviyo yakaoma.

Kugadziridza tekinoroji: kukwenenzverwa nekudzikamisa kutenderedza kwe2D kana 2B ine 100 ~ 120 abrasive zvinhu (JIS R6002).

No.4 -- Kupenya kwakanaka, mitsetse yakanaka pamusoro.

Kugadzirisa maitiro: kukwenenzverwa uye kupisa kutenderedza kwe2D kana 2B ine 150 ~ 180 abrasive zvinhu (JIS R6002).

HL -- Silver grey ine mitsetse yebvudzi.

Kugadziridza tekinoroji: Zvigadzirwa zve 2D kana 2B zvigadzirwa zvine granularity yakakodzera yeabrasive zvinhu zvekupukuta pamusoro inoramba ichiita abrasive tsanga.

MIRRO -- Yakanyanya.

Kugadzira tekinoroji: Zvigadzirwa zve2D kana 2B zvigadzirwa zvine granularity yakakodzera yekukuya uye kupukuta kune girazi maitiro.