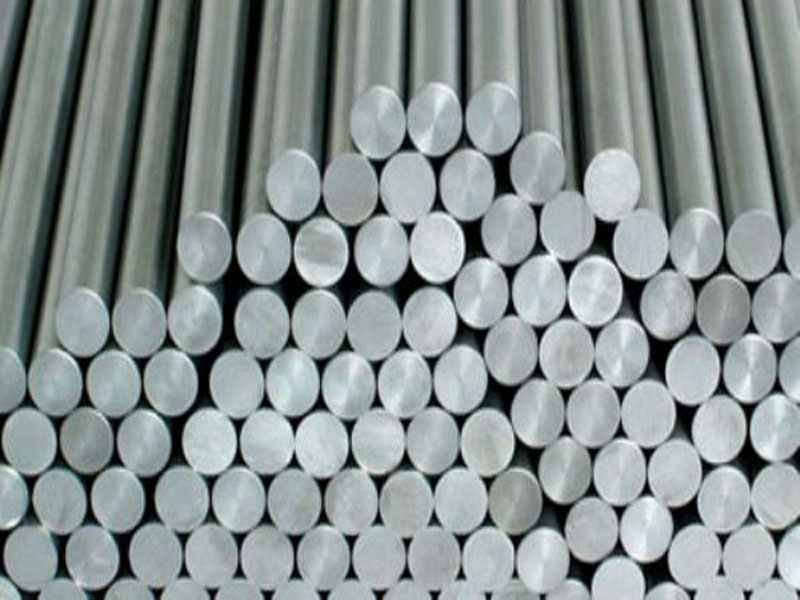

201 Stainless Simbi Bar

Tsanangudzo

Corrosion resistance

Iyo general level yeType 201's corrosion resistance inofananidzwa neType 301's.Munzvimbo zhinji dzakapfava, Rudzi rwe201 runofanira kushanda zvinogutsa pachinzvimbo cheRudzi 301. Rudzi rwe201 rune chiyero chakaderera pane Type 301. Type 201 inokwana 50 °F (28 °C) isingadziviriri kune inoparadza scaling pane Type 301 kusvika kunosvika 1500 °F (816 °C).

Fabrication

Zvakafanana neType 301, Type 201 simbi isina simbi inogona kuumbwa kuburikidza nebhenji kugadzira, roll kuumba, uye brake bending.Asi nekuda kwesimba rayo rakakura, rinogona kunge riine chitubu chakawanda.Kazhinji, chinyorwa ichi chinogona kukweverwa zvakafanana kune Type 301

kana simba rakawanda rikaiswa uye kudzvanywa-kudzika kunosimudzwa, kudhirowa zviitiko.

Weldability

Iyo yakajairwa fusion uye kuramba welding maitiro anofungidzirwa zvakanyanya kuve anokwanisa kujoinha masimbi asina tsvina mukirasi yeaustenitic.Nekuve nechokwadi chekuti ferrite mafomu mune weld deposit, kutarisisa kwakakosha kunofanirwa kutorwa kudzivirira weld "hot cracking".Iyo weld kupisa yakakanganisika nzvimbo inogona kuve yakaoma uye iri panjodzi ye intergranular corrosion mune mamwe mamiriro, senge kune mamwe chrome-nickel austenitic Stainless simbi mamakisi uko kabhoni isingadzorerwe kusvika 0.03% kana pasi.Kuenzaniswa neType 304L Stainless Steel, inova ndiyo inonyanya kufarirwa alloy mukirasi iyi isina tsvina, iyi alloy inowanzo fungwa kuti ine weldability zvakanyanya.Iyo inonyanya kutaurwa yeAWS E/ER 308 ndipo panodiwa weld filler.Mamwe mashoko anogona kuwanikwa mumabhuku ereferensi, ayo anozivikanwa neType 201 Stainless Steel.

Kurapa kwekupisa

Type 201 haina kuomeswa nekurapa kupisa.Annealing: Anneal pa1850 - 1950 °F (1010 - 1066 °C), ipapo mvura inodzima kana kukurumidza kutonhora kwemhepo.Iyo annealing tembiricha inofanirwa kuchengetedzwa yakadzikira sezvinobvira, inoenderana neinodiwa zvivakwa, nekuti Type 201 inoda kukwira kupfuura Type 301.

| Stainless Simbi giredhi | |||||||

| Giredhi | Kemikari yakagadzirwa | ||||||

| C≤ | Si≤ | Mn≤ | P≤ | S≤ | Ni | Cr | |

| 201 | 0.15 | 1.00 | 5.5-7.5 | 0.5 | 0.03 | 3.50-5.50 | 16.00-18.00 |

| 202 | 0.15 | 1.00 | 7.5-10.0 | 0.5 | 0.03 | 4.00-6.00 | 17.00-19.00 |

| 304 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

| 304L | 0.03 | 1.00 | 2.00 | 0.045 | 0.03 | 8.00-12.00 | 18.00-20.00 |

| 309 | 0.2 | 1.00 | 2.00 | 0.04 | 0.03 | 12.00-15.00 | 22.00-24.00 |

| 309S | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

| 310 | 0.25 | 1.50 | 2.00 | 0.04 | 0.03 | 19.00-22.00 | 24.00-26.00 |

| 310S | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

| 316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

| 316L | 0.03 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

| 316Ti | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

| 2205 | 0.03 | 1.00 | 2.00 | 0.03 | 0.02 | 4.50-6.50 | 22.00-23.00 |

| 410 | 0.15 | 1.00 | 1.00 | 0.04 | 0.03 | 0.6 | 11.50-13.50 |

| 430 | 0.12 | 0.12 | 1.00 | 0.04 | 0.03 | 0.6 | 16.00-18.00 |